Anchor design – rocketcomponents

No other permanent anchor is as consistently thought through; this permanent anchor plays an important role in the durable protection of the façade. Common damage to the wall structure caused by the use of often bent conventional scaffold screws is avoided during first-time installation. The real benefit of the permanent scaffold anchor becomes evident when scaffolds are installed later (e.g. in case of renovation work): the permanent anchor points can be simply reused. The opening and connected renewed damage of the façade is completely ruled out. This is possible due to the patented component structure of the isorocket® permanent scaffold anchor.

rocketbase

The precisely dimensioned rocketbase load distribution plates are matched to both the respective surface (concrete or masonry) and also the required subsequent structure thickness. Made of very strong galvanised steel, the rocketbase is wet with the composite glue on the wall-side for blister-free assembly, and is mounted to the wall. This means we can guarantee 100% force dissipation into the respective sub-surface and maximum force absorption for much fewer attachment points than is normal in the market to date. The rocketbase is perfectly mounted using the assembly key rocketkey that is a component of our assembly set.

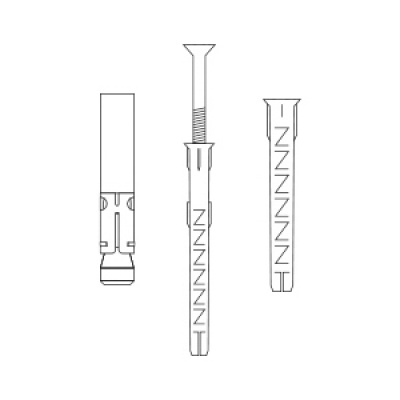

rocketplug

Our rocketplug is a versatile, approved attachment material for walls made of cracked and non-cracked concrete or also masonry (full brick) according to DIN 4426 (German standard) and is used to anchor the load distribution pate rocketbase in the respective surface. For the temporary scaffold anchor according to DIN EN 12811-1:2004-03 (Temporary construction for buildings - Part 1: Work scaffold / German standard) we supply you with corresponding nylon wall plugs in a proven quality that the scaffolder knows from his daily work.

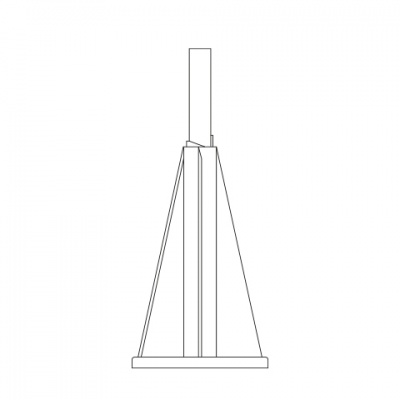

rocketbody

The anchor body rocketbody is the heart of the isorocket® permanent scaffold anchor. It is made of glass-fibre reinforced plastic and is mounted to the load distribution plate, and is tightened with the assembly key rocketkey. Thanks to its cylindrical form, the rocketbody allows thermal insulation to be processed easily and continuously; this is also enhanced by the self-cutting load distribution lamella. The screw channel that is matched to the respective structural thickness (Mini, Medi, Maxi, Mega) is the only permanent anchor that has a special entry and assembly point for the assembly of a joint seal tape, which is specified in all ETICS approvals for corresponding installations. Thanks to the long plastic neck (‘Swan neck’), it is possible to create a perfect connection for the reinforcement and final plaster work. When the scaffold is removed, the protruding part of the anchor body is shortened with the special shortening unit rocketcutter to be level with the façade surface. In this way, the rocketbody and its inserted structural thickness finishes flush to the façade despite any unevenness in the surface.

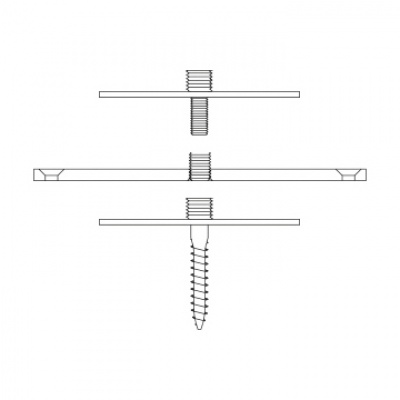

rocketbolt

The eye-bolt rocketbolt is screwed in for professional anchoring of the scaffold into the anchor body. Thanks to the long screw channel (swan neck), the screw does not have direct contact to the ETIC system or the reinforcement or outer plaster at any phase of the façade creation. This strict separation of components prevents plaster flaking when removing the eye-bolt, and guarantees a clean connection. Made of special steel with a diameter of 18 mm, the rocketbolt eye-bolt stands out compared to the otherwise 12 mm screws that are usually used. This screw, which is 50% thicker, ensures much better stability and minimum bending of the screw connection for the lateral load specified in DIN 4426 (German standard) and reduces the number of the anchor points that need to be mounted in a façade surface.

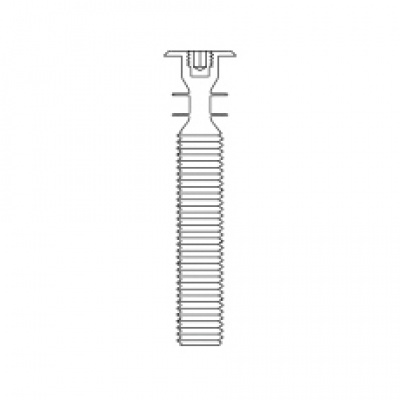

rocketseal

The thermal bridge-free special seal rocketseal is used to close the screw channel perfectly and durably when the scaffold is removed and the rocketbody anchor body is shortened. The rocket seal is not just a seal, it also has a screw connection to the rocketbody that can be opened and closed again repeatedly. In its design, it divides the screw channel into various successive air chambers that guarantee that there are no thermal bridges. The head point has a stainless steel insert for holding an Allen key for the respective assembly step; this even effectively prevents anchor points that are not opened for a long time from becoming ‘chewed’. Not just any ‘plug’ but well thought-through quality in a perfect design made of high-quality plastic that can be ‘painted over’ with all conventional façade paints. When scaffolding is put up again, the special plug is simply twisted out and the isorocket® permanent scaffold anchor is ready for use again.

Australia

Australia Deutschland

Deutschland Österreich

Österreich Schweiz

Schweiz UK

UK USA

USA Canada

Canada Ireland

Ireland Singapore

Singapore Nederland

Nederland